Yes, a board can be cnc milled using Fritzing gerbers… You may need to design the board a little different than you would for a fab shop.īTW, CAD/CAM and CNC machining is my background… I had thought about building another cnc machine and trying this out… sounds like a good winter project… I didn’t set anything up on CopperCam, this was generated out of the box.

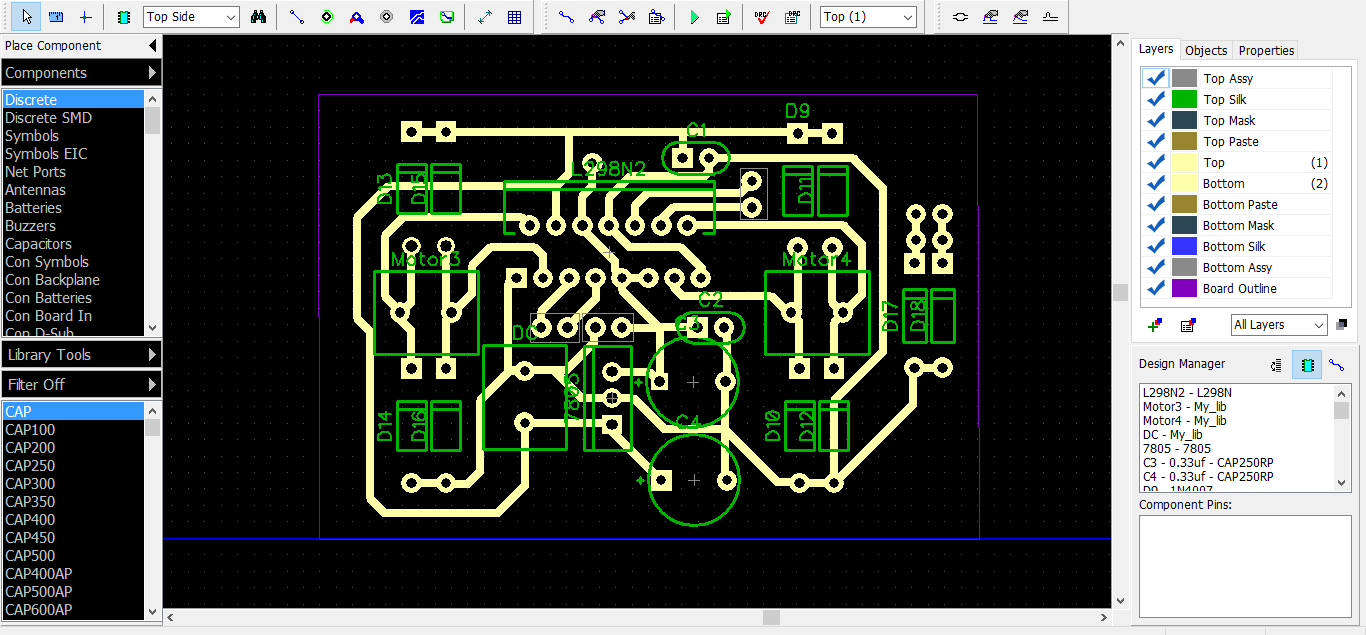

This board has 8 mil trace and a few 0.3 mm laser drill holes, and is not likely it could ever be milled on a cnc machine. Below is a sample of the g-code I generated from this gerber. The gerber I used in CopperCam is the same one I sent to OSH Park. This is a board that I created on Fritzing and had it fabricated by OSH Park earlier this month. In my opinion the best solution would be obtained if the Fritzing generate SVG fully compatible with Inkscape’s tools but this is not in my power. So the solution would be to export a Gerber generated by Fritzing for Eagle generate Gcode to be used by bCNC but Gerber that Fritzing generates is not fully compatible with the Eagle and the result of the migration is unsatisfactory. If there was not a problem I could work the SVG graphic generated by Fritzing ( “xxx_etchcopper_bottom_mirror.svg”) for the negativet it with the Exclusion tool. Try using the tools Union, Difference, Intersection, Exclusion, Division (in the Path tab) in SVGs generated by Inkscape and SVGs generated by Fritzing. This is a problem.Īnother problem with the SVG graphic generated by Fritzing is that they can not be handled by Inkscape just as an SVG graphic generated by Inkscape can be handled by Inkscape itself. I initially tried using the SVG generated by Fritzing but there is some incompatibility between the SVG exported by Fritzing and SVG imported by bCNC because no Fritzing SVG graphic can be imported into bCNC. I want to continue using the Arduino for various reasons even though this is not the best CNC platform.Īmong the formats that can be opened by bCNC I can name the SVG and Gcode but not the Gerber. I do not know another application to do that, so I have to work with bCNC if I want to continue using the Arduino. The bCNC is the application that connects to the Arduino GRBL. (Note: although I do not believe that the CNC is the best way to produce a PCB, I assembled a CNC to study and would like to try this process.)

Diptrace pcb for cnc how to#

The question is how to generate “negative” vector of _xxx_etch_copper_bottom_mirror.svg image, ie, vectors forming where the image content is white. In this case we want to cut which is white but white is just the image background, is not a vector. In _xxx_etch_copper_bottom_mirror.svg graphic, cut where it is black, where we do not want to cut. The CNC “cuts” where there is a vector in the image. The graph of this SVG layer containing the vectors in the proper format for PCBs but not appropriate to generate the gcode used by a CNC, that is, this graph would have to have the “inverted” vectors in the image: the vectors should be present where the image is white.

The Fritzing can generate a set of vectorial SVG graphics for the production of PCBs, among which is especially important _xxx_etch_copper_bottom_mirror.svg graphic to “print” the botton layer. I think that I did not properly formulated this question considering that this is a vector image and I might not get me adequately express in English I apologize. Inkscape can be a tool to change the vector graphic color, but can also be used “Developper tools” from Google Chrome to edit the color of each component vector of the image SVG … but change the vector color does not solve the problem. You answered my question, I thank you for your attention.

0 kommentar(er)

0 kommentar(er)